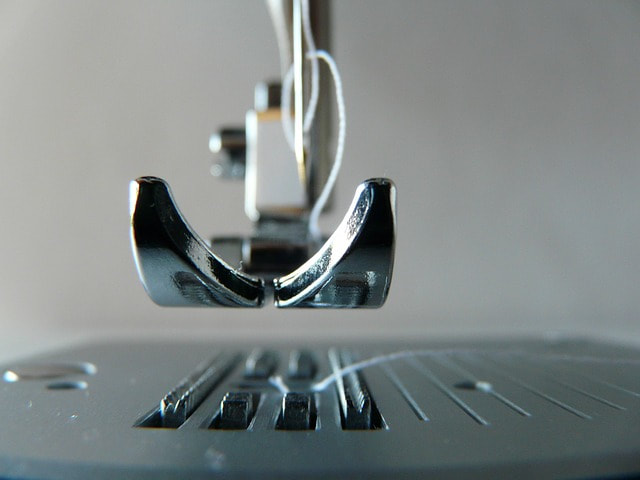

Industrial feet, feed, and needle plateAside from tension issues, one of the most often found problems with industrial sewing machines is keeping an eye on your feet (walking or otherwise), your feed dog(s), and your needle plate.

NEEDLE PLATE-

Here's one of the places that some "unexplained" issues can be resolved. If you're sewing a good thickness of fabric, or a dense fabric, or even stretchy fabric, it is possible for your needle to move out of alignment during sewing and manage to hit the needle plate. A full on needle point hit will almost always break the needle, but if it just glances off, it will only leave a mar in the needle hole on the plate. This can catch on the upper and lower threads, and often effect how your stitch looks, or either of the threads could fray out and tear randomly. |

Details

Your sewing machine guy:I am a Jack-of-Most-Trades that was roped into working on sewing machines, and managed to find a knack for it. I love hilarity, fixing things that are broken, video games, dogs, cats, most other creatures, and sleep. Especially sleep. On here you'll usually find tidbits about recent visits or ADORABLE CREATURES THAT LOVE ON ME WHILE I WORK. There may be ancient machines, there may be unique machines. Archives

July 2020

Categories |

RSS Feed

RSS Feed